IONIC

- Seria: Cloxx - urządzenia metalowe

- Nr produktu: 160005

- Producent:

Informacje podstawowe

Specyfikacja techniczna produktu

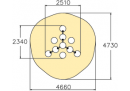

- Szerokość

- 2510 mm

- Max. wysokość upadku

- 1510 mm

- Wysokość

- 1510 mm

- Długość

- 2340 mm

- Min. obszar / Długość

- 4730 mm

- Min. obszar / Szerokość

- 4660 mm

- Min. obszar / Wysokość

- 3310 mm

- Strefa bezpieczeństwa

- 17,1 m2

- Liczba użytkowników

- 10

Informacje o produkcie

- Seria

- Cloxx - urządzenia metalowe

- Nazwa

- IONIC

- Numer produktu

- 160005

- Certyfikaty

- EN 1176-1

- Przeznaczenie wiekowe

- 4+

Ta strona wykorzystuje pliki typu cookie. Jeżeli nie wyrażasz zgody na ich zapisywanie, wyłącz ich obsługę w ustawieniach swojej przeglądarki. Zamknij